Anti-Foam Control Solutions-- Industrial Anti-Foam Solutions for Improved Efficiency

Anti-Foam Control Solutions-- Industrial Anti-Foam Solutions for Improved Efficiency

Blog Article

Ideal Practices for Choosing the Right Anti-Foam Control Remedy for Your Needs

Picking a reliable anti-foam control remedy demands a thorough analysis of your one-of-a-kind functional demands. Secret factors to consider include the particular homes of your process, such as ph, temperature level, and chemical communications, all of which substantially affect the efficiency of defoaming agents.

Understand Your Foam Problem

Frequently, companies come across foam-related problems that can hinder functional effectiveness and product high quality. Foam formation can take place during various procedures, including mixing, fermenting, and transport, and it typically results in tools inadequacies, manufacturing downtime, and enhanced functional expenses. Understanding the underlying reasons for foam generation is important for dealing with the trouble successfully.

Foam can arise from numerous elements, such as the nature of the materials entailed, anxiety degrees, temperature variants, and chemical reactions. Particular surfactants can intensify frothing, while high shear mixing can introduce air, leading to undesirable foam buildup. Furthermore, environmental conditions and the details characteristics of the fluid systems being used can considerably affect foam behavior.

Determining the kind of foam-- whether it is unpredictable or stable-- is likewise necessary. Steady foam tends to linger longer and is much more difficult to take care of, while unstable foam may dissipate a lot more conveniently. Anti-Foam Control Solutions. By analyzing these variables, organizations can get understandings right into their foam issues, enabling them to establish targeted methods to mitigate foam formation and enhance general procedure performance. This foundational understanding is important for choosing an ideal anti-foam control remedy tailored to specific operational needs.

Evaluate Anti-Foam Options

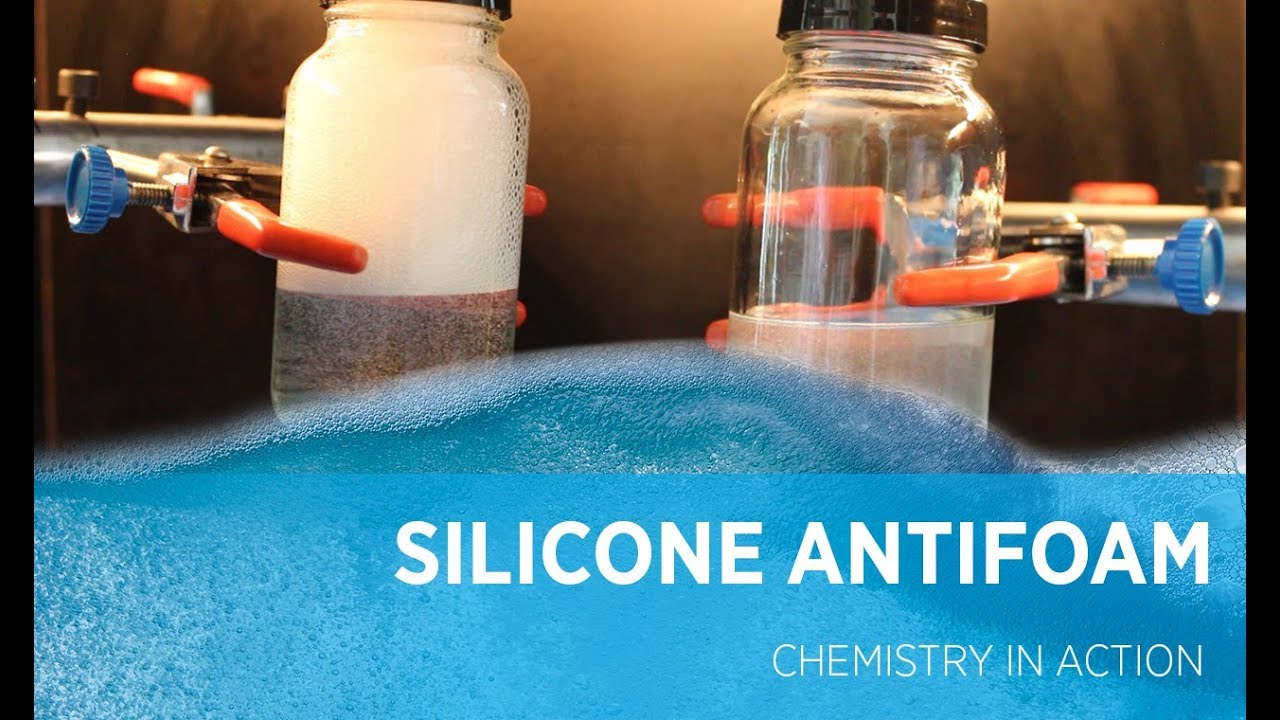

When considering anti-foam options, it is vital to thoroughly evaluate the various formulations available on the marketplace to locate one of the most appropriate service for your specific foam-related challenges. Anti-foam representatives been available in diverse types, consisting of silicone-based, non-silicone, and natural formulas, each offering unique properties and efficiency qualities.

Begin by evaluating the particular application requirements, such as temperature level limits, pH levels, and the kind of foam being created. Silicone-based representatives are understood for their effectiveness in high-temperature atmospheres, while non-silicone options might be more suitable in food processing applications due to regulative factors to consider.

It is likewise critical to consider the price of application and the preferred durability of the foam control. Some solutions may provide instant defoaming activity, while others provide long term stability. Performing small-scale examinations can provide understandings right into the effectiveness of each alternative in real-world conditions.

Think About Application Compatibility

In the realm of anti-foam solutions, ensuring application compatibility is paramount for attaining optimum efficiency. The effectiveness of an anti-foam agent greatly depends upon its capability to function sympathetically within the details specifications of your application, including temperature level, pH, and the existence of other chemicals. Various formulas may execute variably throughout diverse problems, therefore comprehensive screening is crucial.

Begin by recognizing the qualities of your procedure, such as thickness and the nature of the medium in which the anti-foam will certainly be employed. For circumstances, some anti-foam agents might work well in aqueous options however stop working in natural solvents. Furthermore, take into consideration the prospective communications with existing components and products to prevent unwanted impacts.

It is additionally essential to review the method of application. Whether the anti-foam is presented continuously or batch-wise can influence its effectiveness and longevity in the system. Make sure that the picked product is not just suitable with the operational specifications yet also lines up with any kind of regulatory demands significant to your market.

Assess Environmental Influence

Just how does the environmental effect of an anti-foam control remedy influence your overall choice procedure? The eco-friendly footprint of your selected anti-foam agent is extremely important, as it reflects your commitment to sustainability and regulative conformity. Picking an item with minimal environmental consequences can improve your company photo and foster consumer trust fund.

When examining ecological influence, consider the biodegradability of the anti-foam service. Naturally degradable choices are normally better, as they damage down extra swiftly and reduce long-term environmental damage. Furthermore, examine the capacity for bioaccumulation and toxicity to aquatic life. Solutions with high toxicity can pose significant risks to local ecosystems, potentially causing regulatory fines and ecological destruction.

One more essential factor more tips here is the visibility of unsafe compounds. Anti-foams including hazardous chemicals might necessitate special delivery and disposal procedures, complicating and raising operational costs conformity with environmental laws. Therefore, choosing eco-friendly choices can alleviate these threats.

Display and Optimize Efficiency

To optimize the performance of your anti-foam control option, it is important to routinely check and optimize its efficiency. Continuous examination permits the identification of any kind of discrepancies in foam degrees and the subsequent efficiency of the anti-foam agent.

Execute an organized method to check key performance indications (KPIs), such as foam volume, stability, and the action time of the anti-foam representative. Utilize analytical tools and techniques, such as visual assessments, foam height measurements, and specialized sensors, to collect precise information.

In addition, maintain open interaction with suppliers for technological assistance and insights on the current developments in anti-foam modern technology. This proactive strategy not only aids in attaining optimal performance yet also lessens functional disturbances and enhances general procedure efficiency. On a regular basis revisiting and fine-tuning your anti-foam approach makes sure that you are effectively handling foam-related difficulties, inevitably leading to enhanced efficiency and price financial savings.

Final Thought

In conclusion, choosing the appropriate anti-foam control remedy requires a comprehensive analysis of particular application demands, including temperature level, pH levels, and chemical compatibility. Strenuous testing for instant and prolonged defoaming effectiveness is crucial, as is consideration of ecological influences and regulative conformity. By prioritizing environment-friendly options and constantly checking performance, functional performance can be enhanced while successfully minimizing foam-related challenges. Sticking to these ideal practices will help with enlightened decision-making in anti-foam control solutions.

Picking a reliable see this here anti-foam control remedy necessitates a comprehensive assessment of your distinct operational demands.In the realm of anti-foam options, making sure application compatibility is extremely important for attaining optimum efficiency.Just how does the ecological influence of an anti-foam control remedy affect your general choice process?In final thought, choosing the suitable anti-foam control service necessitates a comprehensive evaluation of specific application needs, consisting of temperature level, pH levels, and chemical compatibility (Anti-Foam Control Solutions). Adhering to these ideal practices will certainly help Learn More with informed decision-making in anti-foam control solutions

Report this page